Bhor, Pune, Maharashtra

- GST NO. : 27AACCC7648B1ZS

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

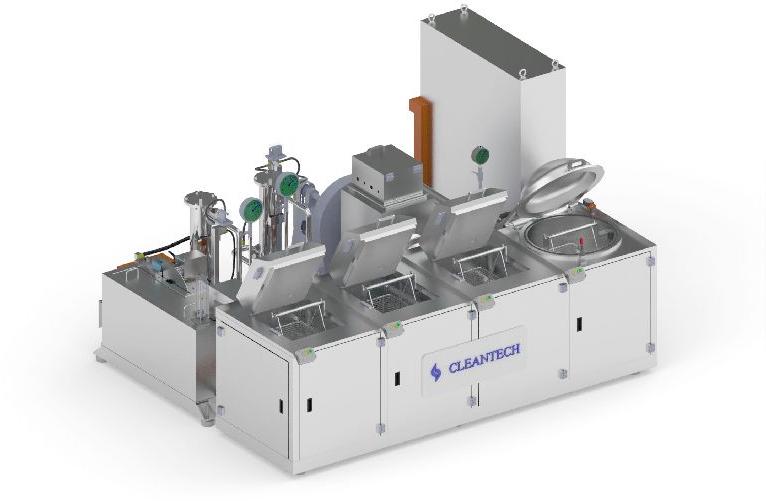

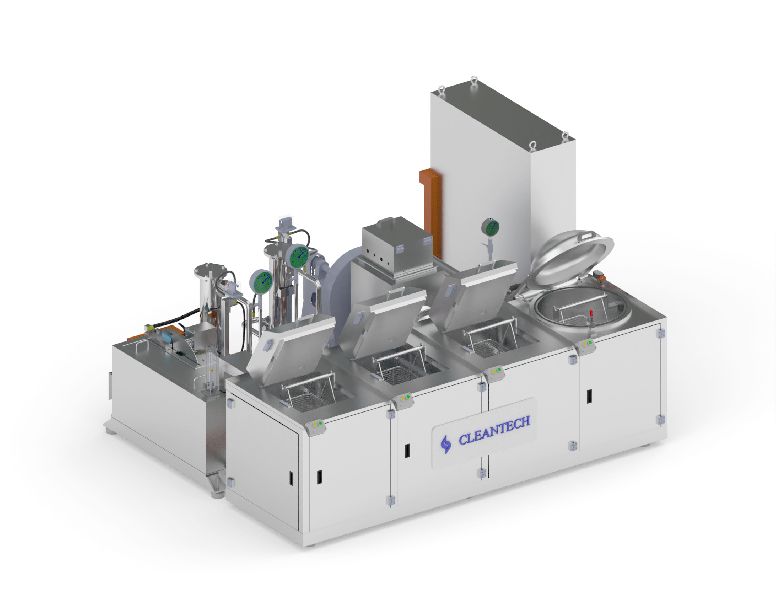

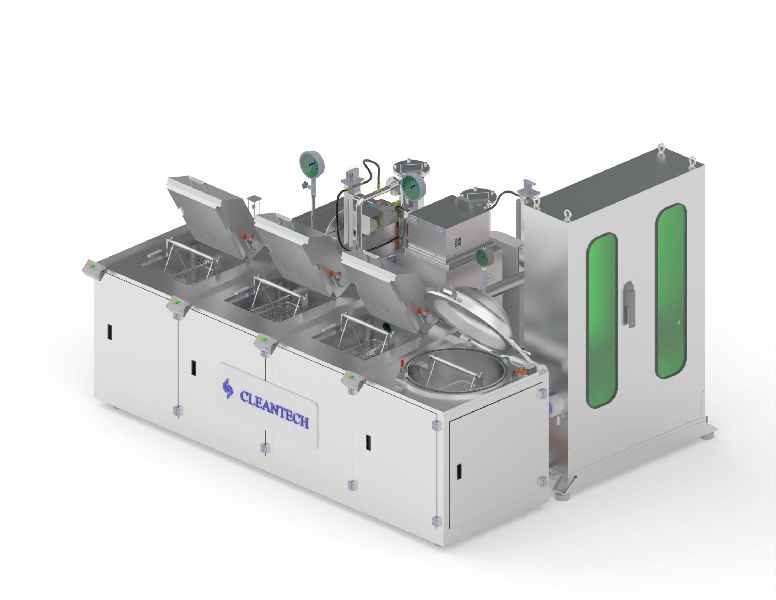

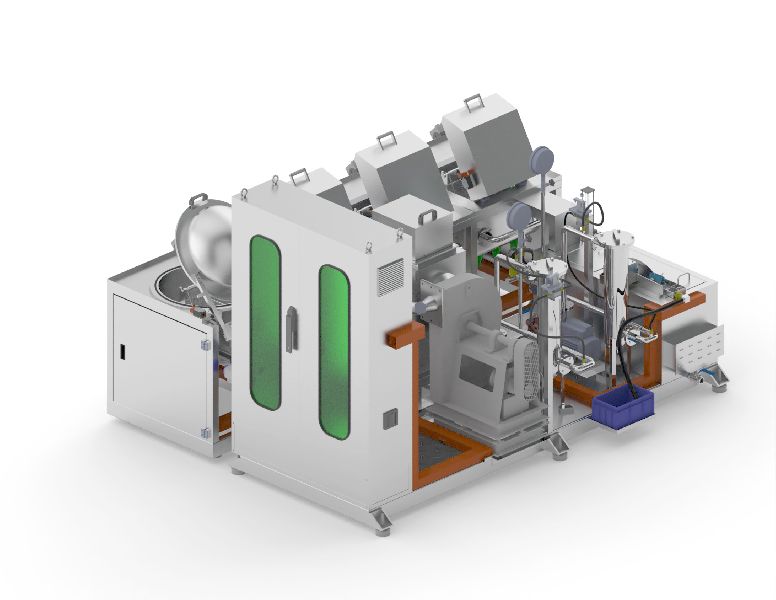

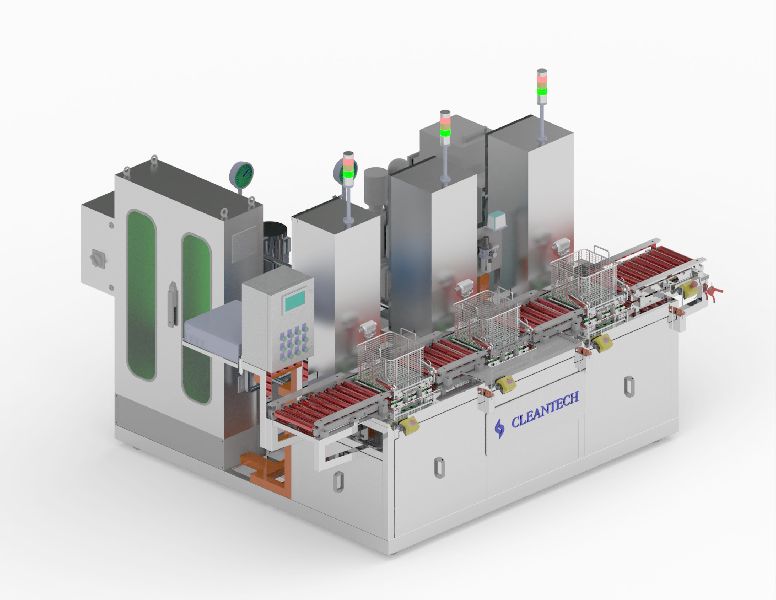

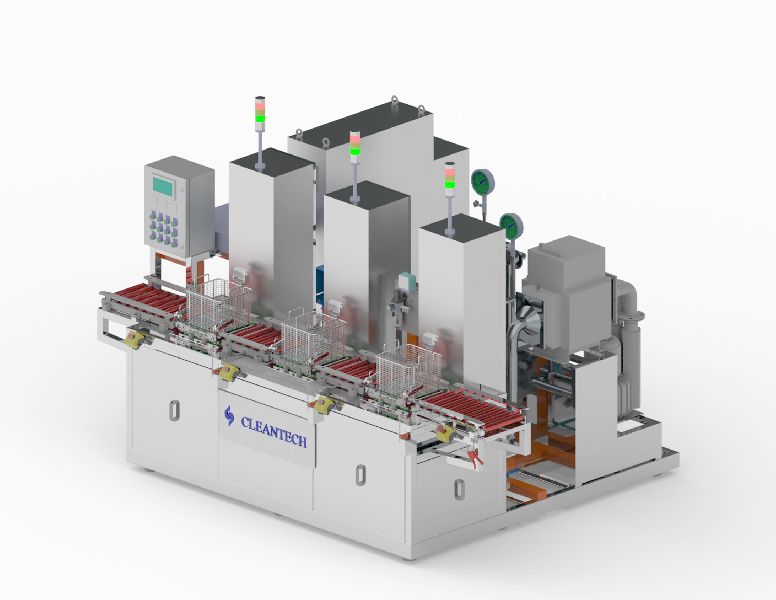

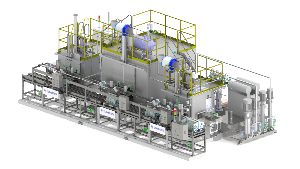

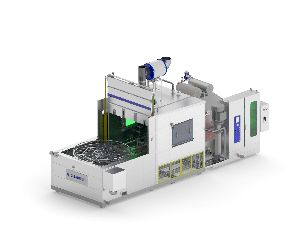

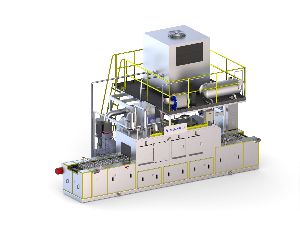

Introduction

Ultrasonic cleaning machines are most suitable when the contamination levels are low. Components are complex and precision cleaning is required. These are best suited in combination with spray and dip washers.

Description

- Ultrasonic washers uses the cavitations technique to clean the components

- In this process, bubbles are produced in the cleaning solution bath by the transducers and these bubbles then explodes on the surface of the part.

- Due to the explosion the contaminant present on the surface gets detached from the surface and the cleaning of the part is achieved

- Usually these machines have more takt time

Application

- CONNECTING ROD

- CRANKCASE COVERS

- ENGINE PARTS

Features

- SS construction,

- highly reliable,

- low maintenance,

- state of the art after sale service.

- Environment friendly, aqueous cleaners.

- low running cost.

- Operator safety is built-in in the design of machine.

- The various options of energy for tank heating like heat pump, gas heating, heat exchanger, water heating steam heating are available.

- Total solution to cleaning problems.

Looking for "Ultrasonic Washing Machine" ?

piece

Explore More Products