Bhor, Pune, Maharashtra

- GST NO. : 27AACCC7648B1ZS

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

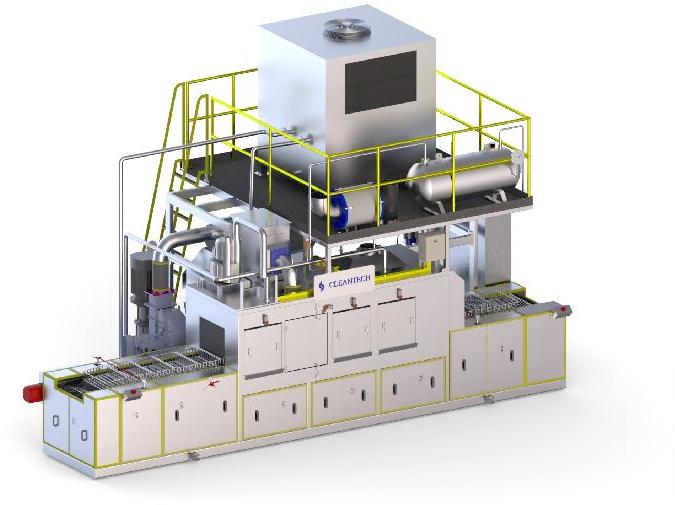

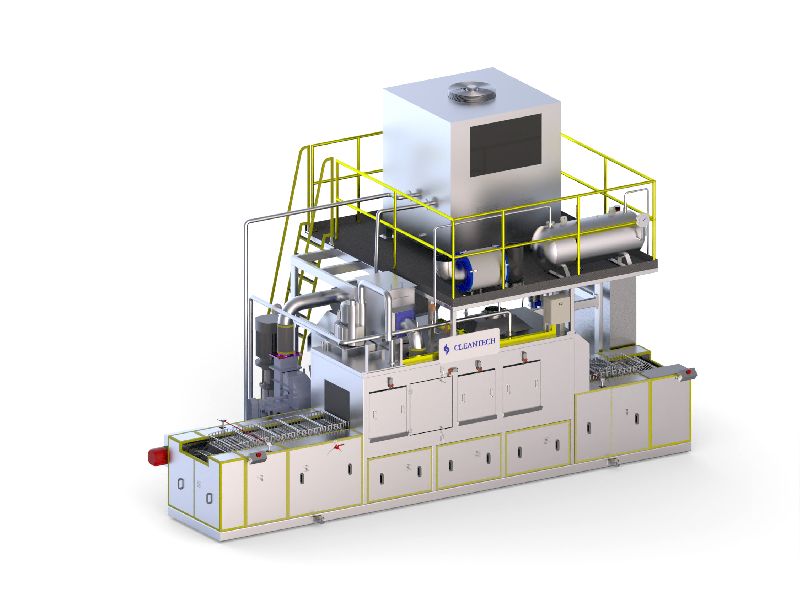

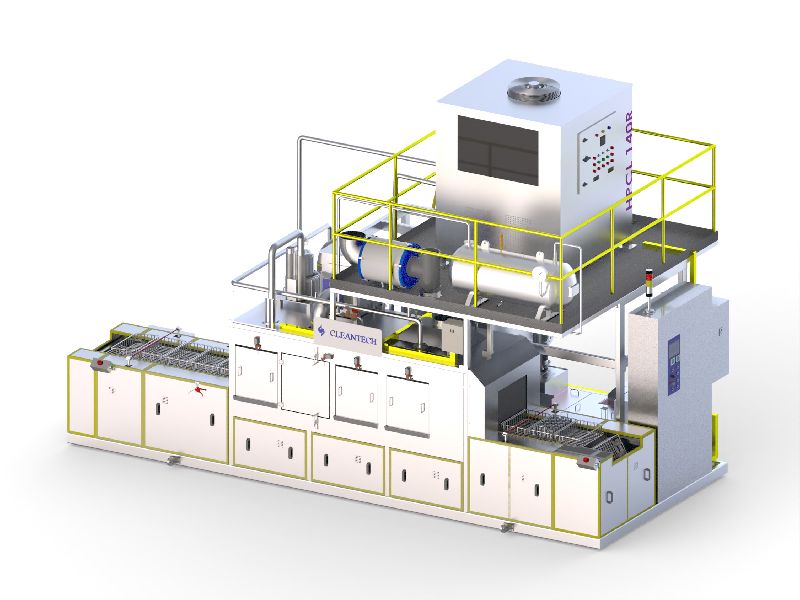

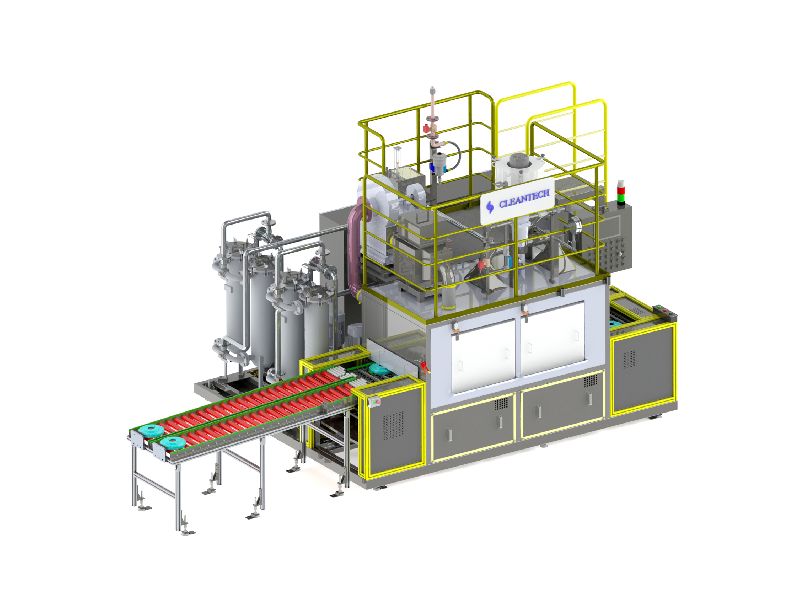

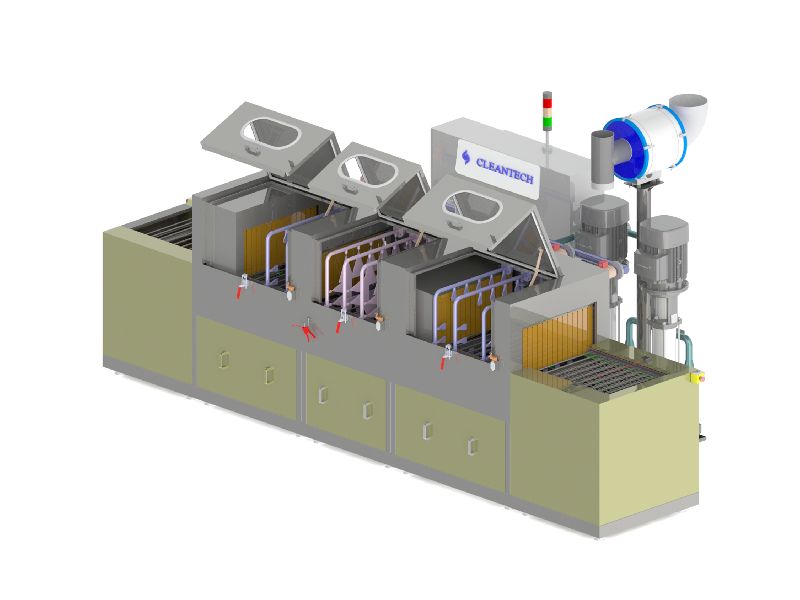

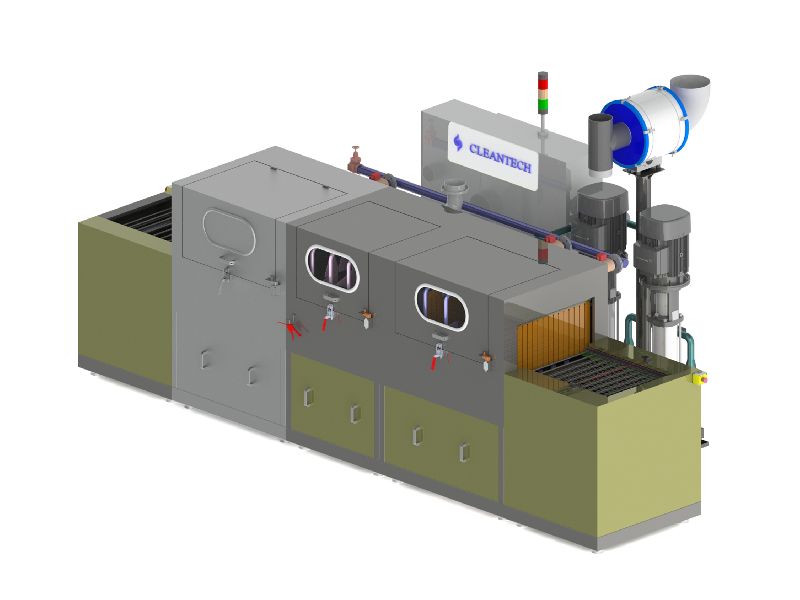

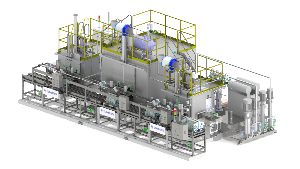

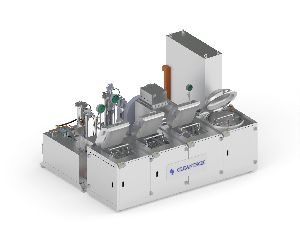

Introduction

Conveyorized cleaning machine are very useful for high volume production with both general and specific cleaning options. These machines are mostly suitable for medium-sized components.

Description

- Conveyorized machines can have either a continuous conveyor or Linear Indexing/stop and go, conveyor.

- Components are load at one end and unload from the another end.

- These machines are user friendly.

- Operations are performed simultaneously.

- Linear Indexing/Stop and Go type conveyor is used for precise cleaning.

Application

- PUMP HOUSING

- COMPRESSOR PARTS

- PLASTIC BINS AND TRAYS

- SPRINGS

- PIPES

- PULLEYS

- ROTORS

- TOOLS & CUTTERS

- WIND TURBINE COMPONENTS

- AXLE BOX

- ROLLER BEARING

- CYLINDER HEAD

- CYLINDER BLOCKS

- CRANKSHAFT

- BALANCER SHAFT

- CONNECTING ROD

- GEARS

- CRANK CASE

- CRANK COVER

- GEAR BOX HOUSING

- CAM SHAFT

- GEARS AND SHAFTS

- AXLE HUB & HOUSING

- BRAKE DRUM & HUB

- FRONT AXLE BEAM

- ALLOY WHEELS

- MISCELLANEOUS MACHINE COMPONENTS

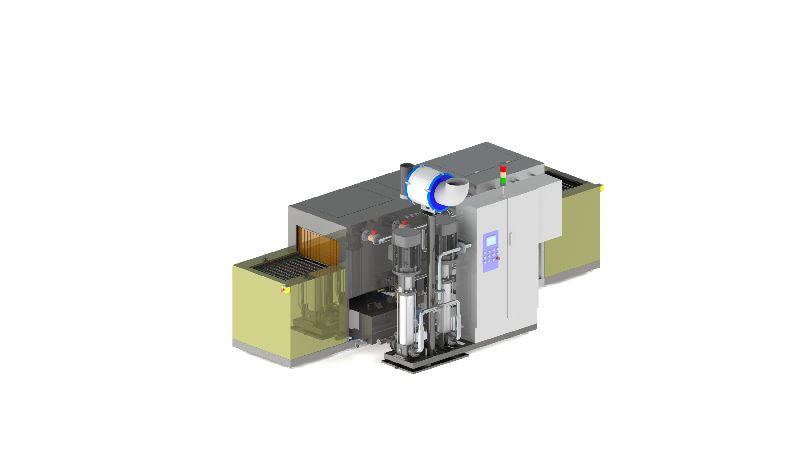

Features

- SS 304 is used in water contact surfaces.

- Excellent operational reliability

- Low maintenance cost

- 24×7 service support

- Low running cost

- Built in safety

- Multi-stage filtration

- Cold/ Hot air blow options

- HMI panel with indicators

- MES/IOT options

- Various options for tank heating (like Heat Pump, Gas Heating, Heat Exchanger, Steam , etc.) are available

Looking for "Conveyorised Washing Machine" ?

Piece

Explore More Products