Bhor, Pune, Maharashtra

- GST NO. : 27AACCC7648B1ZS

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

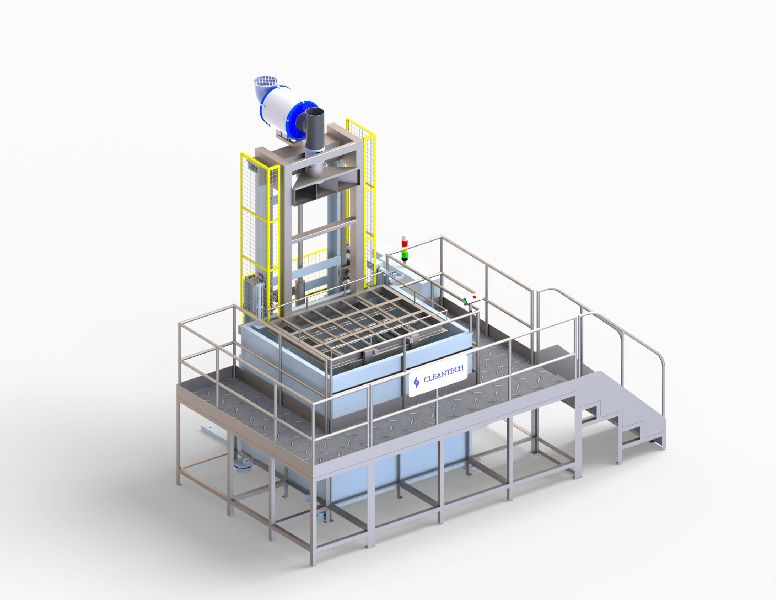

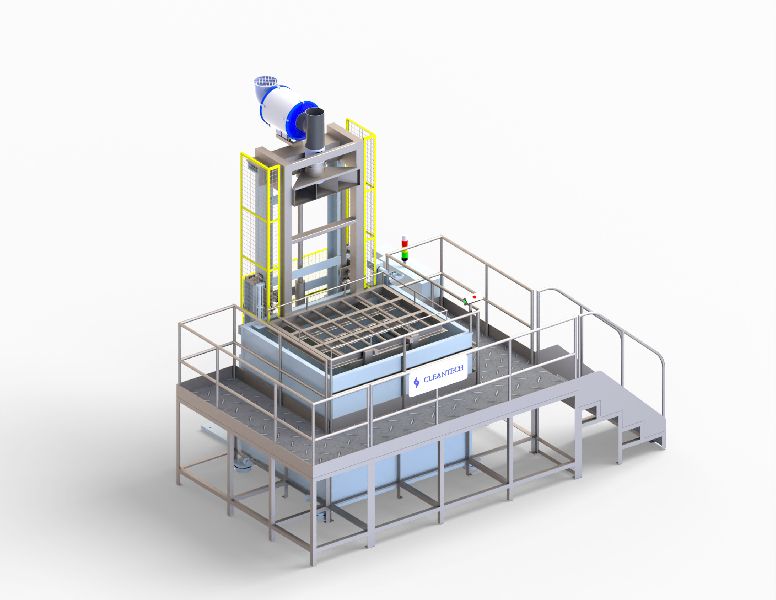

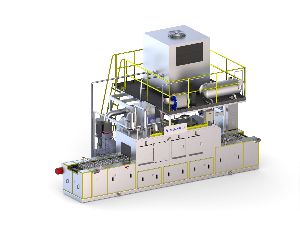

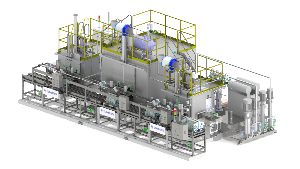

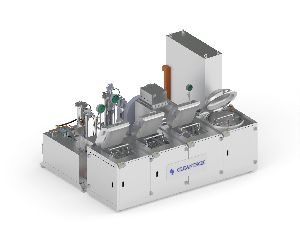

Introduction

Dip and Dunk cleaning machines are used for intermediate cleaning of components having intricacies. In order to minimize contamination levels these machines are of great help.

Description

- Mainly used to Loose the Oil & dust from the surface Components.

- These type of machines are mainly used in intermediate cleaning.

- Components can be manually loaded & unloaded.

- Offline filtration can be provided according to the requirement.

- Compact in size.

- PLC-based control panel.

- Losses the dirt in critical areas & oil holes easily.

Application

- GEARS

- SHAFTS

- BEARINGS

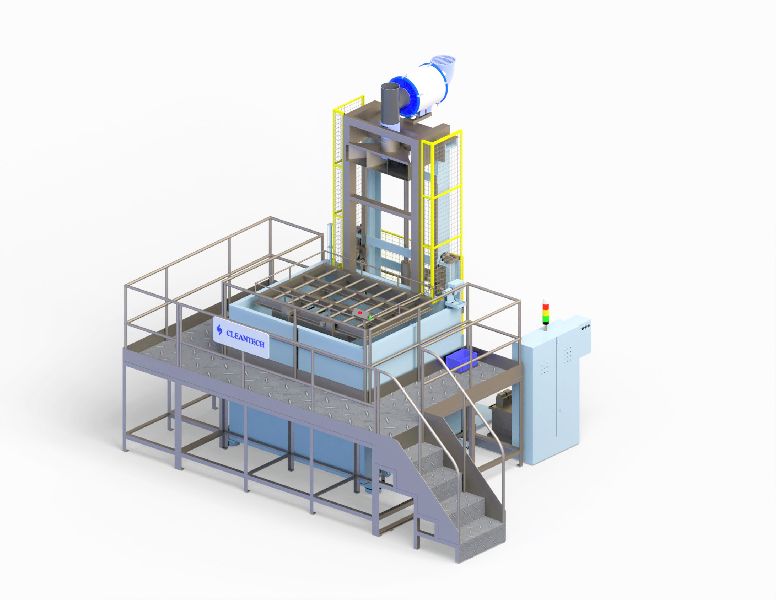

Features

- SS 304 is used in water contact surfaces.

- Excellent operational reliability

- Easy material handling

- Low maintenance cost

- 24×7 service support

- Low running cost

- HMI panel with indicators

- Various options for tank heating (like Heat Pump, Gas Heating, Heat Exchanger, Steam, etc.) are available

Looking for "Dipping & Dunking System" ?

Explore More Products